Integrated machine carpet production management software is a comprehensive software package that includes dozens of different subsystems.

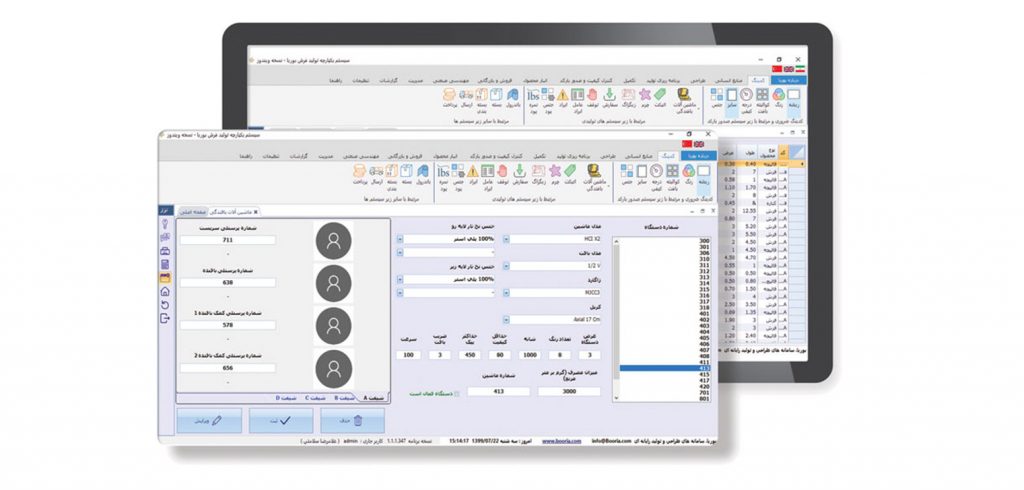

Integrated systems is the title for systems that comprehensively manage all the resources of the production unit (factory), whether physical resources such as equipment and machinery, as well as human and financial resources and any other available resources, and its characteristics. Provides planning and optimal use of resources.

As a result, by fully implementing the organization’s resource planning system, it creates many benefits in the business. Most businesses have a special need for manufacturing systems, human resources, support, strong and integrated finance. This software is programmed by Borya Company specifically and exclusively for machine-made carpet factories.

Integrated machine carpet production management software that can be run in Windows environment

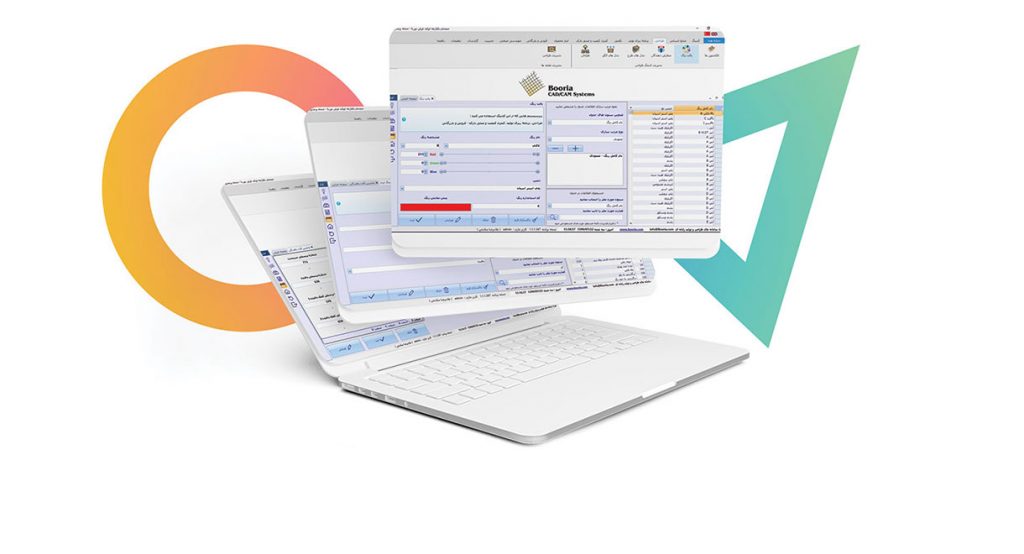

In the integrated management software for the production of machine-made carpets, an attempt has been made to consider the actual processes that have taken place, from design and ordering to packaging and loading. Unlike traditional software, the integrated system is designed in such a way that each component is able to perform tasks independently, and if a change is made in one component, the other components do not change or have serious problems. The different parts of the factory use an integrated database and there is no disconnection between the data and the data is not duplicated and redundant. In addition to these features, it can be reduced to factors such as reducing the volume of daily activities, eliminating reprocessing and optimizing the use of resources, user-friendly and powerful environment, flexibility in complying with laws (in the fields of sales, exports and imports, productivity rights, etc.) And pointed to quick and easy access to integrated system reports

Integrated management software coding system for machine carpet production

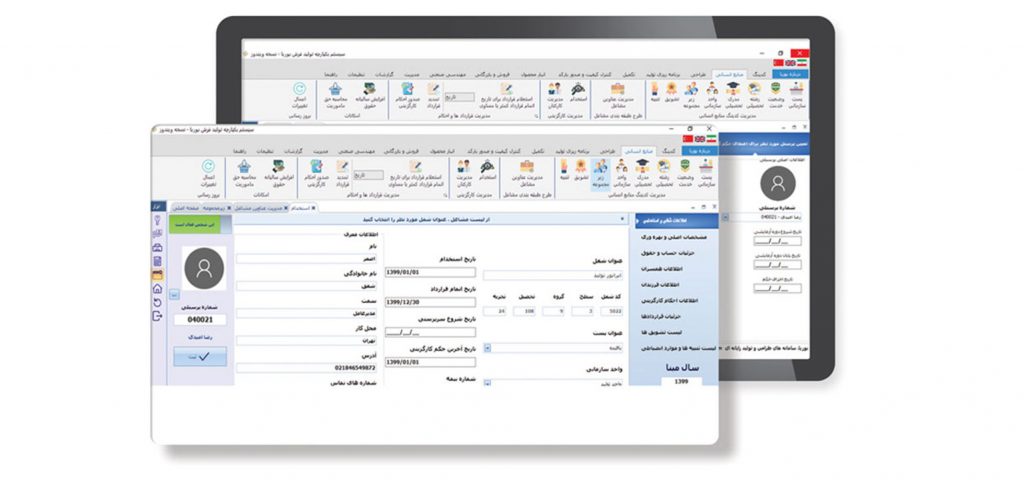

Also in this system, information is completed during mechanized steps and step by step, and finally a unique barcode is issued for each product produced. This flow of information makes all factory processes such as design, production, completion, packaging, quality control, sales and trade, industrial engineering, management, etc. with very accurate and efficient details, easily traceable and reportable

By issuing a unique barcode for each board or roll of the product, all the production information along with that carpet board can be obtained. Information such as: weaving order date, initial order amount, product color, designer name, customer name, weaver name, shift work , The name of the supervisor, qualitative and quantitative defects during weaving, the names of the operators responsible for the process of completing the carpet and dozens of other types of information. In this way, if the carpet is returned from your collection of products in the store, all the information related to that carpet can be reported and tracked

If you need any more information, please leave a message and our customer support team will contact you as soon as possible